Applicable Scope and Characteristics of Galvanized C purlin

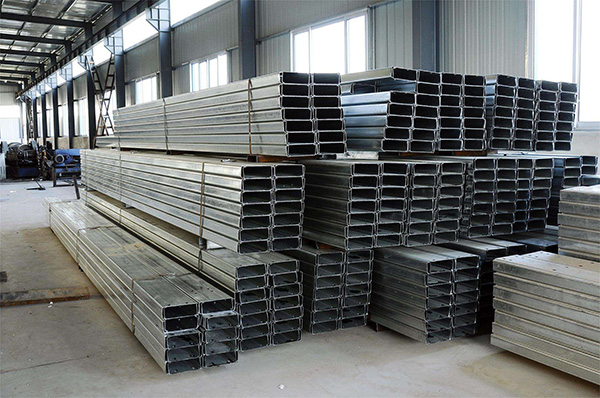

Galvanized C purlin is a new type of steel with uniform wall thickness, excellent cross-section performance and high strength. Compared with traditional hot rolling, the same strength can save 30% of material.

The galvanized C-section steel has the advantages of adjustable size and high compressive strength. The section size of cold-formed section steel is lightweight, but it conforms to the stress characteristics of roof purlin, so that the mechanical efficiency of steel can be fully utilized by light distribution. Many kinds of fittings can be connected into different combinations with beautiful appearance. Using shaped steel purlin can reduce the weight of building roof and the amount of steel used in engineering. Therefore, it is called economical and efficient steel. It is a new building material to replace traditional steel purlin such as angle steel, channel steel and steel pipe.

Scope of application

Galvanized C-section steel is widely used in purlin and wall beam of steel structure building, and can also be self-assembled into lightweight roof truss, bracket and other building components. In addition, it can also be used for pillars, beams and arms in light industry manufacturing.

Outstanding features

Galvanized C-section steel has uniform zinc layer, smooth surface, strong adhesion and high dimensional accuracy. All surfaces are covered by zinc layer. The zinc content on the surface is usually 120-275g/. It has long service life, corrosion resistance and durability. It is a kind of galvanized C-section steel with the strongest protection.

Message to this supplier